Why is Safety Measures of Employees Needed?

A Safety Instructions for Employees system is essential for managing high-risk tasks safely, ensuring compliance with safety regulations, and minimizing operational disruptions and environmental impact. Safety monitoring system helps identify and control workplace hazards through clear safety protocols, comprehensive risk communication, and structured instructions on critical procedures such as isolation and lockout/tagout. By guiding employees through task-specific safety measures, it enhances awareness and accountability.

The system also supports regulatory compliance by documenting detailed information on safety instructions, training records, incident reports, and inspection results. Overall, a well-defined safety instruction process reinforces a culture of accountability, promotes operational safety, and ensures that every employee performs tasks under clearly communicated and controlled conditions.

About Safety Information Management System

Employees are required to use the OccuCare Employee Safety Management System to uphold workplace safety, ensure compliance with regulatory standards, and promote a proactive safety culture. The system must be actively used to monitor real-time safety data, report incidents immediately, and support routine safety audits. Accurate reporting of hazards, near-misses, and incidents through the system is essential for timely corrective actions and risk mitigation. Employees should follow scheduled safety checks and maintenance activities prompted by the system to prevent workplace accidents and disruptions.

The system also tracks compliance-related activities such as safety training, inspections, and certifications, which employees must complete and record accurately. By using data-driven insights and predictive tools within the system, employees can identify potential risks early and take preventive action. Overall, consistent and responsible use of the OccuCare Employee Safety Management System is crucial for maintaining a safe, compliant, and efficient work environment.

Feature of Safety Information Monitoring System

Risk Assessment & Hazard Management

The system provides advanced tools to identify workplace hazards and assess associated risks, fully aligned with the local safety regulations.

Design of Safety Management Systems

Utilizes smart conditional logic to design effective safety management systems

Regulatory Compliance & Documentation

Industrial safety system enables automated generation of safety reports and compliance documentation.

Workplace Monitoring & Diagnostics

Supports real-time monitoring of workplace safety conditions, workplace safety monitoring and control system performance.

Integration & Interoperability

Easily integrates with industrial control systems such as PLCs, SCADA, and DCS using standard protocols like API and OPC UA.

User & Access Management

Implements role-based access control (RBAC) with secure user authentication

Risk Assessment & Hazard Management

The system provides advanced tools to identify workplace hazards and assess associated risks, fully aligned with the local safety regulations.

Design of Safety Management Systems

Utilizes smart conditional logic to design effective safety management systems

Regulatory Compliance & Documentation

Industrial safety system enables automated generation of safety reports and compliance documentation.

Workplace Monitoring & Diagnostics

Supports real-time monitoring of workplace safety conditions, workplace safety monitoring and control system performance.

Integration & Interoperability

Easily integrates with industrial control systems such as PLCs, SCADA, and DCS using standard protocols like API and OPC UA.

User & Access Management

Implements role-based access control (RBAC) with secure user authentication

What makes us effective

Proactive Risk Prevention

Industrial safety system identifies potential hazards by analysing real-time operational data and historical incidents.

Real-Time Oversight of All Work Activities

Industrial Safety Monitoring System provides centralized monitoring of all ongoing tasks, including work permits, equipment isolations, contractor activities, and maintenance operations.

Intelligent Decision Support

Built-in analytics and AI tools continuously evaluate safety controls and risk trends. Employees benefit from smarter work planning, improved focus on high-risk operations, and simplified audit readiness through automated documentation and tracking.

System-Wide Integration

Seamlessly connects with existing systems like CMMS, ERP, EHS, and operations platforms to create unified workflows.

Feature and Benefit that Provide Value

World Wide Top Rated Health & Safety Software

Audio Episodes

Our Recent Podcasts

Listen to our series of podcasts that expose you to a broad array of concepts. Whether you're looking for the latest trends or want to hear customer experience, our podcasts will be a treat for your ears.

Overview about Occucare - occupational health software

Welcome to Occucare's Podcast! In today's episode, we're diving into the world of ,Occupational Health and Safety Software where we'll explore how organizations can safeguard their employees' well-being, boost efficiency, ensure compliance, and drive tangible improvements through innovative solutions.

Explore

Occucare - Occupational Health Management Software

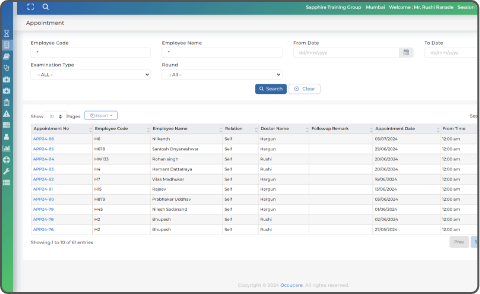

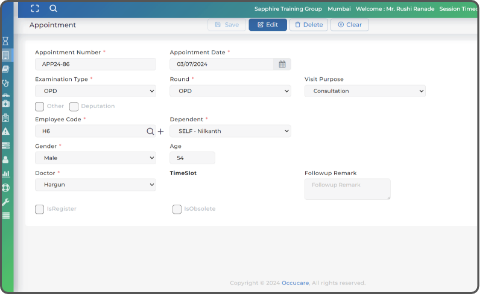

Occupational Health Management solution gives employees access to their medical information across the company, allows for centralized storage and tracking, and assures regulatory compliance. When employees are due for physicals, vaccines, audiometric testing, and other important assessment tasks, the system's robust logic sends out automated reminders. OccuCare's occupational health modules provide a comprehensive and important toolkit for managing all clinical activities for occupational health professionals..

Explore

What Is EHS Management Software? And How Will It Help You?

Welcome, everyone, to another episode of Occucare Health & Safety Software.I'm your host, and today we have an important topic to explore – What is EHS Management Software? We'll dive into what it is, how it works, and most importantly, how it can help you and your organization.

ExploreAwards

We are honored to be recognized for our great services as a leading organization.

Our Clients

The Brands That Trusts Us

We did a great job with these companies to digitize their Occupational Health & Safety Operations

Key Module Insights

Explore comprehensive video tutorials for each key module of our health and safety management software, empowering you to master every feature effortlessly.

Achievements Complete

Helping organisations to achieve health and safety compliance.

20+

Years Experience

100%

Client Retention

200+

IT Professional

150+

OHC Digitized

Explore Our Software

Our Case studies

What Our Clients Say

Process We Follow

An examination of the customer-defined problem statement is part of the ideation phase for OccuCare. Our team of experts formulates the idea in concept.

A software system consisting of essential components, a hosting network, and a development environment containing data modules is built upon the product architecture.

Once the requirements are well defined, we align the technical resources and assign tasks to each person. We give documentation to start the design and development process.

The quality assurance step includes build installation, system testing, problem fixes, user acceptability testing (UAT), and test report preparation since quality is essential to the success.

Change requests, impact analyses, and the completion of any outstanding paperwork are all finished during this stage of knowledge transfer.

Numerous variables, like the software's importance, maturity level, community size, and resources for attaining sustainability, will influence how sustainability is approached.

We are available to assist our clients with UAT, training, final source code deployment, and platform launch on their behalf.

According to the parameters set forth in our agreement, we offer free service and support. In addition, we offer additional monthly or annual packages based on your needs.

Let's Discuss With Us

Organizations can profit from the versatile, adjustable, and tailored health and safety software from OccuCare. Let's connect to explore!

Subscribe us and Get the latest updates and news